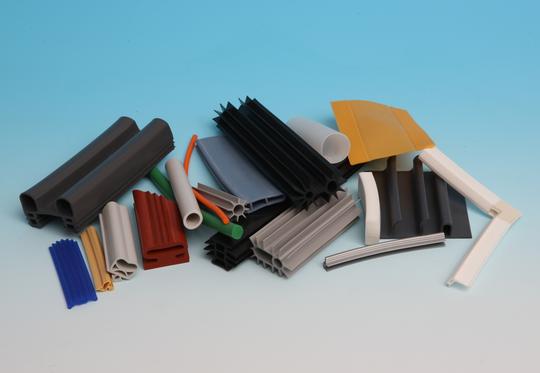

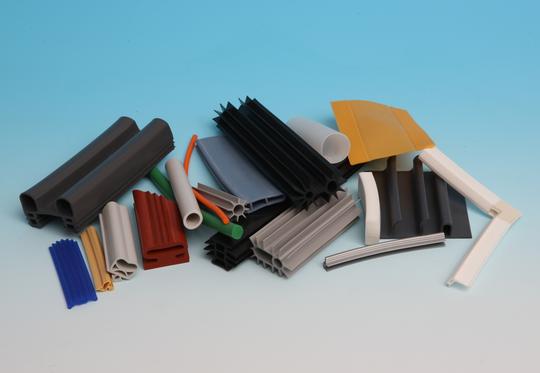

We are producing silicone profiles by the extrusion of material

through a die (template) that defines their required shape. The extruded

profile is then stabilized by a high-temperature thermal shock. The

final heat treatment is made by means of continuous vulcanization in

horizontal and tunnels and in a finishing vulcanizing oven. Our

manufacturing program involves silicone tubes, various shape profiles,

window and door weather-stripping, facade strips and microporous silicon

rubber products.

We can make them in various colour versions. Owing to the properties

of materials used, the application of silicone profiles is particularly

suitable in equipment for which a healthy operation is essential very

good insulation characteristics, resistance against ozone ageing or

which

is intended for demanding thermal conditions, such as drying ovens, furnaces, engines, electrical household appliances etc.

Production of profiles as per the customer's drawings is a matter of

course. We are capable of producing extruded profiles of any shape,

maximum sectional area being 1 250 mm2.

We also have at our disposal the technology for continuous cutting of profiles and their subsequent jointing to a desired size.

For circular seals, we can obtain outer diameter up to 60 mm. The

dimensions of sectional seals above 60 mm must be consulted with our

specialists.

The window weather-stripping SILLEN of various shape versions is

intended to seal windows and doors with different installation

technologies. Compared with similar seals from other materials, silicone

rubber seals have a longer service life, feature better resistance to

solar radiation and a very good shape memory.