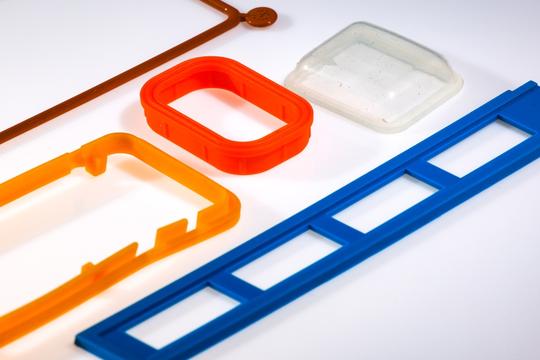

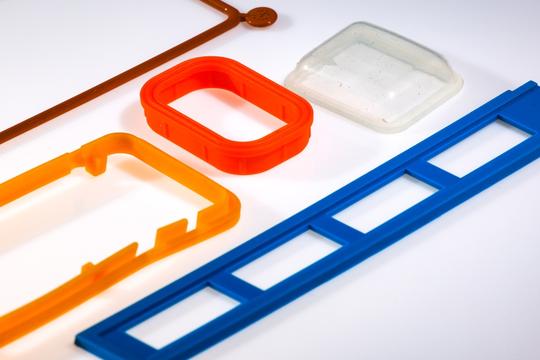

Silicone products

The characteristic properties of silicone rubber products comply with

special requirements for healthy products, better high-temperature

resistance in comparison with common rubbers, high outdoor ageing

resistance, and UV resistance. These rubbers have good electrical

insulating properties. They can be glued. For final products, any needed

colour can be chosen.

The products from silicone rubbers resist the temperatures in the

range from - 60 °C up to +200 °C, compounds with special additives up to

+300 °C, or possibly -100 °C. Their applicability in oils is limited to

oils with aniline point higher than 100. The products can be largely

used in health service, automotive, aerospace and construction

industries, and in household products.

Silicone mechanical rubber

Silicone parts are manufactured based on the customer's requirements

from solid or liquid silicones on injection moulding or conventional

moulds.

We use injection moulding technology on vertical and horizontal

presses. Moulds for solid silicon up to a maximum size of 590 x 740 mm

can be used in injection moulding machines while the maximum dimensions

for liquid silicone are 650 x 650 mm..

For the production of parts in conventional moulds, we are using the tools up to a maximum size of 800 x 800 mm.

The silicone rubber product group involves profile parts manufactured

as per the customer's requirements, various flat rings, cups,

dust-protection bellows, plugs, stops, springs, diaphragms, and other

parts.

We are capable of supplying silicone sheets of various hardness, 250 x 320 mm in size and 1 - 20 mm thick.

We are also offering silicone sheets 1 200 mm wide and 0.3 - 10 mm thick. Maximum length of a roll is 10 m.